Fabric For Cinema Walls

Send forespørsel

1. Produktintroduksjon av stoff til kinovegger

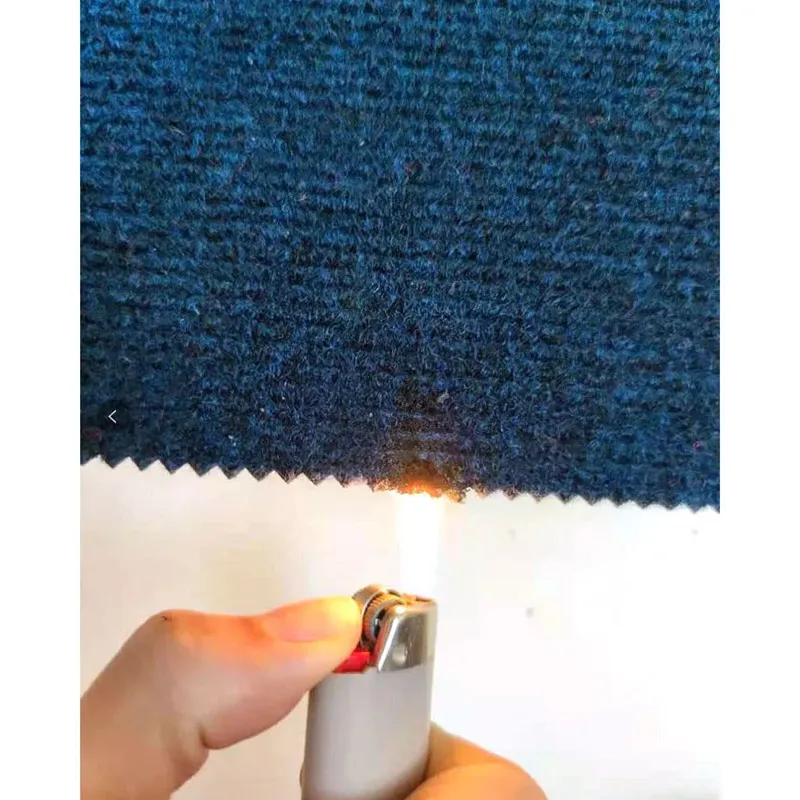

Qdboss use polyester fabric for cinemas walls. Polyester fiber, commonly known as "polyester". It is a synthetic fiber obtained by spinning polyester formed by polycondensation of organic dibasic acid and diol, referred to as PET fiber, which belongs to polymer compound. The activated carbon coating is added on the back to make it flame ratardant.

The main component is graphite, which is flame-retardant. Grapheme is a key national support project. The expansion rate of graphite is 300, which can expand instantly when exposed to high temperatures, preventing oxygen from contacting textiles, smoking and reducing smoke density. Carbonized in fire, no dripping, environmentally friendly flame retardant product

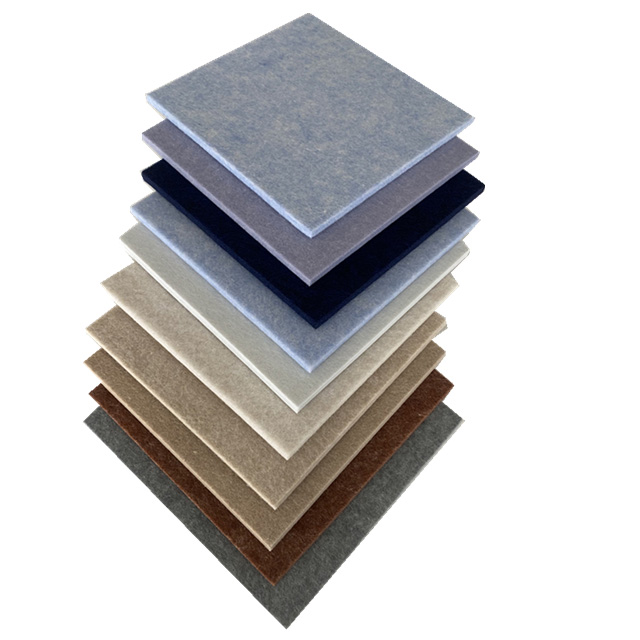

2. Specification of Fabric for cinema walls

|

Kjerne |

Polyester |

|

Thickness |

2mm |

3 Videre bearbeiding av stoffet til kinovegger

The width of the fabric is 1.5m. It can be cut to different sizes such as 1200x1200, 1200x600, 600x600, 300x300, or in round, hexagon shape, or any irregular shapes. Then it is used to wrap the fiberglass.

Og stoffet kan også brukes sammen med rammene for det stedbygde akustiske veggbehandlingssystemet

Den hvite fargen kan også skrives ut med mønstre eller bilder, for å gjøre den mer dekorativ.

4 Hvorfor velge Qdboss akustisk stoff til kinovægge

1. Qdboss has ten years production experience for acoustic panels, flame retardant fabric and meltblown fabric

2. Vi har tusenvis av prosjekter for å bevise god kvalitet og service, spesielt i kinoindustrien. Topp 10 kinoer bruker vårt kinoakustiske panel med det flammehemmende stoffet

3. 7 workshops and experienced workers to ensure the fast and production and delivery

4. 24/7 available for any question about acoustic panel and fabrics.

5. Komplett sett med SGS-testrapport tilgjengelig for brann, termisk motstand, frigjøring av formaldehyd

6. Qdboss is the supplier for several famous brand at home and abroad

5 Slik installerer du stoff til kinovegger

Cut the fiberglass and fabric to required size according to the drawings. Then harden the edge of the fiberglass to make it tough and dry it. After than wrap the fabric to the fiberglass with E0 grade glue.

The fabric wrapped fiberglass panel can be put on the wall directly with air nail gun or glue.